White Fused Alumina Grades for Polishing & Precision Use

What is White Fused Alumina (WFA)?

White Fused Alumina (WFA) is a high-purity synthetic abrasive made by fusing calcined alumina in an electric arc furnace. It features high hardness, sharp edges, low iron content, and excellent thermal resistance—ideal for applications requiring precision and cleanliness.

- Al₂O₃ Purity: ≥ 99%

- Typical Sizes: F12 to F220 (macro), F240 to F2000 (micro)

- Applications: Grinding tools, lapping, polishing, ceramics, precision casting

White Fused Alumina Grit

Sharp-edged macro grits (F12–F220) for high-speed grinding, abrasive wheels, and ceramics processing.

ISO Certified | Factory Direct

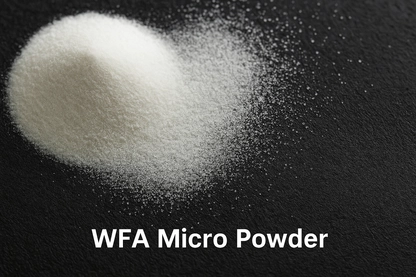

White Fused Alumina Micro Powder

F240–F2000 fine powders for ultra-precision polishing, lapping, and microabrasive applications in optics and electronics.

ISO Certified | Factory Direct

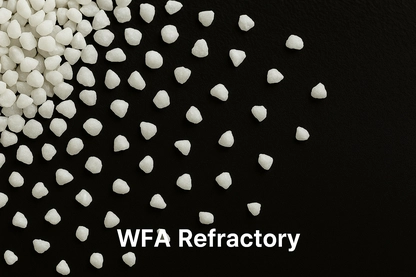

White Fused Alumina for Refractory

High-purity aggregate ideal for refractory bricks, insulating castables, and precision high-temp components.

ISO Certified | Factory Direct