From the perspective of structural ceramics, nano-aluminum oxide fine ceramics can be divided into wear-resistant parts, structural parts, refractory parts, carriers, acid-resistant parts, and insulating parts, etc.

From a functional point of view, nano-aluminum oxide has a variety of functions such as electrical, optical, chemical, biological, sound-absorbing, thermal, and mechanical (see Table 1).

| Functional Applications |

|---|

| Integrated circuit substrates, packaging, spark plugs, Na-S battery solid electrolytes, sensors. |

| Optical function: high-pressure sodium vapor lamp light-emitting tubes, laser materials. |

| Chemical function: control of chemical reactions, purification of exhaust gases, catalyst supports, corrosion-resistant materials, enzyme carriers. |

| Biological function: artificial bones, artificial tooth roots. |

| Thermal function: heat-resistant, thermal insulation structural materials. |

| Mechanical function: grinding materials, cutting materials, bearings, precision mechanical parts. |

Applications of Nano-Aluminum Oxide (VK-L05C) Fine Ceramics

The nano-aluminum oxide fine ceramics made with nano-aluminum oxide (VK-L05C) as the main raw material have been widely used in high-tech fields and many industries due to their multiple functions, which are briefly introduced as follows:

Applications in the Electronics Industry

1. Ceramic multilayer substrates for multi-chip packaging

The manufacturing methods of nano-aluminum oxide ceramic multilayer substrates for packaging include thick film printing, green sheet lamination, green sheet printing, and hybrid thick-thin film methods.

2. High-pressure sodium lamp light-emitting tubes

The transparent nano-aluminum oxide ceramics formed by polycrystalline opaque nano-aluminum oxide are applied in high-pressure sodium lamps, with a lighting efficiency twice that of mercury lamps, opening up a new way to improve lighting efficiency. Transparent nano-aluminum oxide fine ceramics not only have good light transmission, but also have properties such as high temperature resistance, corrosion resistance, high insulation, high strength, and low dielectric loss, making them an excellent optical ceramic material, which can also be used for microwave oven windows.

3. Nano-aluminum oxide ceramic sensors

Using the structural characteristics and properties of nano-aluminum oxide ceramic grains, grain boundaries, and pores as sensitive elements, nano-aluminum oxide ceramic sensors are applied in high-temperature and corrosive gas environments, enabling accurate and rapid detection and control. The types of applications include temperature, gas, and temperature sensors.

Biomedical Applications of Nano-Aluminum Oxide (VK-L05C) Ceramics

Polycrystalline nano-aluminum oxide has been used as a biomedical functional material since 1969. Nano-aluminum oxide fine ceramics used in medical engineering include single crystals and sintered polycrystals. Currently, the United States, West Germany, Switzerland, and the Netherlands are widely using polycrystalline nano-aluminum oxide to make artificial teeth and bones. The main biomedical ceramic material is nano-aluminum oxide, used for tooth roots and joints. The contact angle between nano-aluminum oxide fine ceramics and body fluids is closest to that of human teeth. To date, there are more than 20 types of biomedical ceramics, and nano-aluminum oxide is the most widely used.

Nano-Aluminum Oxide (VK-L05C) Ceramic Cutting Tools

The hardness (Hr) of nano-aluminum oxide is 2700-3000, the modulus of elasticity (kg/mm2) is 35000-41000, the thermal conductivity is 0.75-1.35*103 J/m·h·°C, and the coefficient of thermal expansion is 8.5×10-6/°C (room temperature to 1000°C). While utilizing these properties, Al2O3-TiO2 and Al2O3-ZrO2 ceramic systems have also been developed to improve the toughness and thermal shock resistance of nano-aluminum oxide ceramic cutting tools, meeting the needs of high-speed cutting.

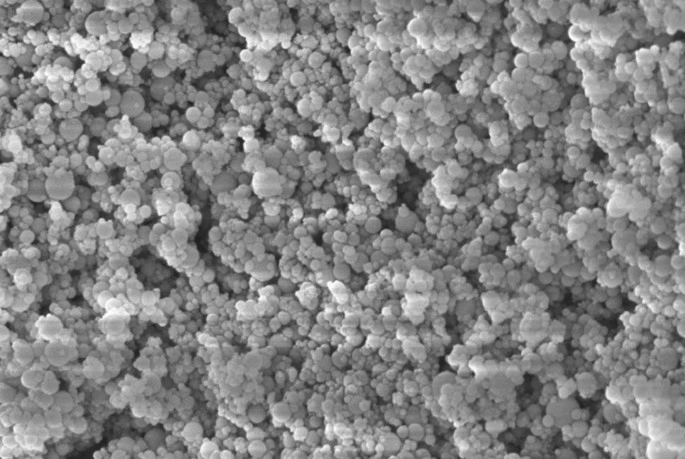

The control of nano-aluminum oxide grain size during the sintering process is a crucial step in determining the quality of the cutting tools. If hot isostatic pressing (HIP) is used, the grain size can be reduced to 0.3-0.5 microns. The bending strength of nano-aluminum oxide cutting tools can be improved to 900-1000 MPa.