Introduction

Fused alumina stands as a critical material in the abrasives manufacturing industry, renowned for its unparalleled hardness, durability, and adaptability. With an ever-increasing demand for precision tools and refined surfaces in today’s industrial landscape, fused alumina plays a vital role in shaping, cutting, grinding, and polishing. Its superior performance has made it indispensable, providing the foundational material needed to meet the rigors of modern manufacturing.

What is Fused Alumina?

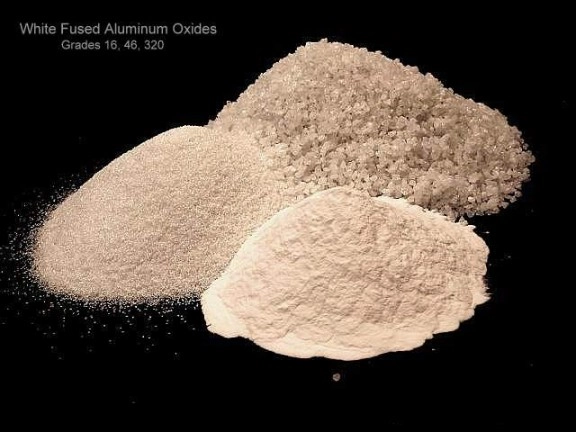

Fused alumina is a synthetic crystalline substance created by fusing aluminum oxide at exceedingly high temperatures. The process results in a highly stable and durable material that possesses exceptional hardness. Available in several types, including white, brown, and pink, each variety is formulated for specific industrial applications, depending on its purity and the presence of trace elements such as titanium or chromium.

Historical Development of Fused Alumina

The origins of fused alumina can be traced back to the early 20th century, when it emerged as a superior alternative to natural abrasives. It quickly gained prominence due to its consistency, hardness, and resistance to heat. Technological advancements throughout the decades further enhanced its production processes, allowing for greater control over its properties and enabling its widespread use in a variety of industrial sectors. The material’s evolution has paralleled the advancement of modern manufacturing technologies, making it a central component in abrasives today.

The Manufacturing Process of Fused Alumina

Fused alumina production begins with the selection of high-purity aluminum oxide. This raw material is fed into an electric arc furnace where it is heated to temperatures above 2,000°C, causing it to melt and fuse into a crystalline form. Once cooled, the solidified alumina is crushed into fine particles and meticulously graded by size to ensure uniformity. These graded grains are then used in various abrasive products, where their controlled properties deliver consistent performance.

Properties of Fused Alumina in Abrasives

Fused alumina’s extraordinary hardness is one of its most defining characteristics. Ranking near corundum on the Mohs hardness scale, it is ideal for high-performance abrasive applications. Its chemical inertness ensures it does not react with most substances, allowing it to withstand harsh environments. Additionally, its remarkable thermal stability makes it capable of enduring the extreme temperatures typically encountered during industrial processes.

Applications of Fused Alumina in Abrasive Products

The applications of fused alumina in abrasives are vast and varied. Grinding wheels, an essential tool in material removal processes, rely on fused alumina grains for both coarse and fine grinding tasks. In sandblasting, fused alumina provides consistent surface preparation, cleaning, and finishing results. Additionally, it is extensively used in polishing tools, offering smooth finishes across metals, ceramics, and glass substrates, enhancing their aesthetic and functional properties.

Comparison with Other Abrasive Materials

When compared with other abrasive materials such as silicon carbide or zirconia alumina, fused alumina stands out for its balance between hardness, toughness, and cost-efficiency. While silicon carbide is harder, it is also more brittle, making it unsuitable for certain long-term applications. Zirconia alumina offers higher toughness but at a steeper cost. Fused alumina strikes a balance between these characteristics, offering excellent durability and performance across a wide range of applications at a competitive price.

Advantages of Fused Alumina in Manufacturing

The consistency of fused alumina gives it a distinct advantage in manufacturing processes. Each grain is uniform in size and composition, ensuring predictable behavior in abrasive products. This predictability leads to lower material waste, reduced downtime, and increased efficiency. In large-scale production, the cost-effectiveness of fused alumina also plays a significant role, allowing industries to achieve high-performance results without incurring excessive costs.

Key Factors in Selecting Fused Alumina for Abrasive Manufacturing

Choosing the right type of fused alumina for a particular application hinges on several factors. Grain size is a critical consideration—coarse grains are optimal for heavy material removal, while finer grains are better suited for polishing and finishing. Purity is another important factor; higher purity fused alumina is required in applications where contamination could affect the final product. These considerations help manufacturers create abrasives that meet the exacting needs of various industries.

Challenges in Fused Alumina Production

The production of fused alumina presents a few key challenges, most notably the high energy consumption required for the smelting process. Maintaining the high temperatures necessary for production is energy-intensive, which can drive up costs. Additionally, managing impurities in the raw materials is crucial, as any contamination can negatively impact the final product’s performance. However, advancements in production technology continue to address these challenges, making the process more efficient and sustainable.

The Role of Fused Alumina in Precision Grinding

Precision grinding relies heavily on fused alumina for its ability to deliver sharp, clean cuts with minimal deviation. Industries like aerospace and automotive manufacturing, where accuracy is paramount, benefit from the fine control that fused alumina abrasives provide. Its durability allows tools made with fused alumina to maintain their sharpness and effectiveness over prolonged periods, ensuring consistent, high-quality results in precision applications.

Fused Alumina for Coated Abrasives

In coated abrasives, such as sandpaper and abrasive belts, fused alumina is the material of choice for its sharpness and wear resistance. The abrasive grains are bonded to a backing material using resins, which ensures the product's longevity and flexibility. These abrasives are versatile and can be used in both dry and wet conditions, making them suitable for a variety of industrial applications, from woodworking to metal finishing.

Fused Alumina in Refractory and Wear-Resistant Materials

Beyond abrasives, fused alumina is valued for its role in the production of refractory and wear-resistant materials. Its high melting point and resistance to thermal shock make it a prime choice for use in furnace linings and kiln furniture. In wear-resistant applications, fused alumina protects machinery from abrasion and corrosion, extending the lifespan of critical industrial components and reducing the need for frequent maintenance.

Sustainability in Fused Alumina Manufacturing

As industries increasingly focus on sustainable practices, the production of fused alumina has evolved to meet these demands. Energy-efficient smelting processes and the recycling of used abrasives have become more widespread, reducing the overall environmental impact of manufacturing. By reusing fused alumina in secondary applications, manufacturers can reduce waste and lower their carbon footprint, aligning with broader global sustainability goals.

Innovations in Fused Alumina Technology

Innovation in fused alumina technology continues to push the boundaries of what is possible in abrasives manufacturing. Advances in grain refinement have led to the development of superfine alumina particles, which are used in micro-abrasive applications for ultra-precise finishing. Further innovations in cooling techniques during production have resulted in energy savings and reduced costs, making the production process more efficient and sustainable.

The Future of Fused Alumina in Abrasive Manufacturing

The future of fused alumina in the abrasives manufacturing industry is bright, driven by advancements in technology and the growing demand for high-performance materials. Automation and artificial intelligence are set to revolutionize manufacturing processes, enhancing precision and efficiency in abrasive production. As the global market for abrasives continues to expand, fused alumina will remain a cornerstone material, providing the reliability and performance that industries require.