CBN grinding wheels (cubic boron nitride) are mainly used for grinding hard and tough workpieces and cannot replace diamond SDC grinding wheels for grinding cemented carbide and non-metallic hard materials. When grinding, only oil-based coolant can be used, not water-based coolant. Because, under high grinding temperatures, CBN will undergo a chemical reaction when meeting an alkaline aqueous solution. The CBN grinding wheel will decompose in an alkaline solution at 300°C and can be slightly decomposed in boiling water. As a result, the crystal shape of the abrasive grains will be destroyed.

SDC grinding wheels (diamond) will not stick to chips when grinding and cutting ferrous materials. They are ideal for grinding quenched steel, high-vanadium high-speed steel, aluminum high-speed steel and other metal materials that are sensitive to grinding temperature. Grinding wheel.

1. Different heat resistance:

- CBN grinding wheels (cubic boron nitride) can withstand high temperatures of 1250-1350 degrees Celsius.

- SDC grinding wheels (diamond) are heat resistant up to 800 degrees Celsius.

2. Different uses:

- CBN grinding wheels are mainly used to process hard and tough materials, especially ferrous metals, such as various steel parts, cast iron, etc. Workpieces: auto parts - crankshafts, camshafts, etc., hydraulic parts, compressor parts, etc.

- SDC grinding wheels are mainly used to process hard and brittle materials, such as carbide, ceramics, glass and other workpieces.

3. Costs are different:

- In terms of production cost, the price of CBN grinding wheels is much higher than that of SDC grinding wheels. If the workpiece processing allows, diamond grinding wheels are better than CBN grinding wheels.

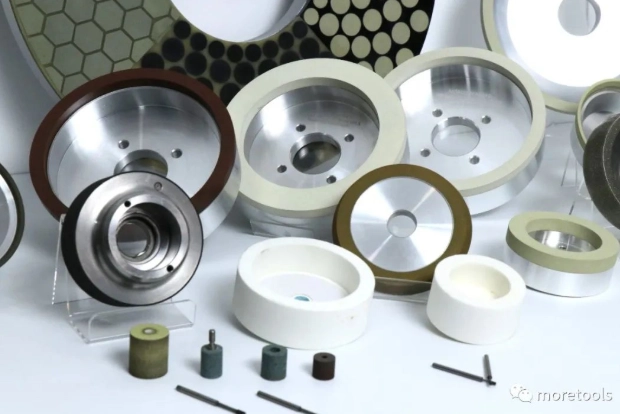

In short, CBN grinding wheels and SDC grinding wheels are both superhard grinding wheels. The scope of application of the two grinding wheels complements each other. Their abrasive toughness, hardness, and durability are dozens or hundreds of times that of corundum grinding wheels.