Abrasives are essential materials used in various industries for grinding, cutting, polishing, and shaping surfaces. They play a crucial role in processes such as metalworking, woodworking, and construction. This article serves as an introduction to abrasives, exploring their types, properties, applications, and the importance of selecting the right abrasive for specific tasks.

What are Abrasives?

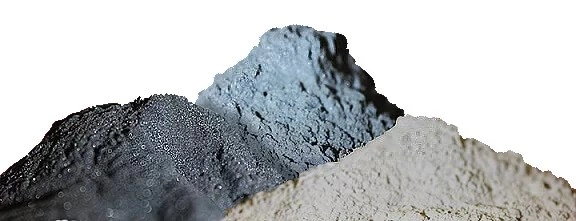

Abrasives are materials that have the ability to wear away or remove material from a surface through friction. They are typically hard, granular substances that are applied to a workpiece using different tools and techniques. Whether for large-scale machinery or for personal DIY projects, abrasives may be used. Abrasives can be natural or synthetic and are available in various forms, such as powders, grains, pastes, and solid blocks.

Types of Abrasives

Natural Abrasives

Natural abrasives are derived from naturally occurring minerals or rocks. Some common examples of natural abrasives include:

- Emery: Emery is a natural abrasive composed of corundum and magnetite. It is known for its hardness and is commonly used for polishing and grinding metal surfaces.

- Pumice: Pumice is a lightweight, porous volcanic rock. It is used as an abrasive for polishing and removing surface imperfections on glass, ceramics, and metal.

- Sandstone: Sandstone is a sedimentary rock composed of sand-sized grains. It is commonly used as an abrasive in grinding wheels and sandpaper.

Synthetic Abrasives

Synthetic abrasives are manufactured materials designed to mimic the properties of natural abrasives. Some commonly used synthetic abrasives include:

- Aluminum Oxide: Aluminum oxide is a versatile abrasive known for its hardness, toughness, and durability. It is used for grinding, polishing, and surface preparation in various industries.

- Silicon Carbide: Silicon carbide is a synthetic abrasive known for its extreme hardness and high thermal conductivity. It is commonly used for grinding hard materials such as ceramics, glass, and carbide.

- Diamond: Diamond is the hardest known natural material and is widely used as an abrasive in various forms, including powders, pastes, and grinding wheels. Diamond abrasives are used for precision grinding, lapping, and polishing of hard materials.

- Cubic Boron Nitride (CBN): CBN is a synthetic abrasive that exhibits similar properties to diamond. It is commonly used in the machining of hardened steels, high-speed steels, and superalloys.

Properties of Abrasives

Abrasives possess various properties that determine their effectiveness and suitability for specific applications. Some important properties of abrasives include:

- Hardness: Abrasives need to be harder than the material they are intended to grind or polish. The hardness of an abrasive determines its ability to remove material effectively.

- Toughness: Toughness refers to the ability of an abrasive to resist fracture or breakage during use. Tough abrasives can withstand high stress and provide longer tool life.

- Grain Shape: The shape of abrasive grains can vary, such as angular, rounded, or blocky. Grain shape affects the cutting action and surface finish achieved during grinding or polishing.

- Size and Grit: Abrasive particles come in different sizes, typically measured by grit size. Smaller grit sizes indicate finer particles, resulting in smoother finishes, while larger grit sizes are more aggressive and suitable for material removal.

Applications of Abrasives

Abrasives find applications in various industries and processes, including:

- Metalworking: Abrasives are used for grinding, deburring, and polishing metal surfaces to achieve desired tolerances, surface finishes, and edge preparations.

- Woodworking: Abrasives are employed for sanding and shaping wood surfaces, removing imperfections, and preparing them for finishing.

- Construction: Abrasives play a role in surface preparation, such as removing coatings, smoothing concrete or stone surfaces, and preparing them for painting or sealing.

- Automotive: Abrasives are used for refinishing automotive bodies, repairing paintwork, and preparing surfaces for adhesion.

- Precision Manufacturing: In precision manufacturing, abrasives are crucial for achieving tight tolerances, smooth finishes, and precise shaping in industries such as aerospace, medical devices, and electronics.

Selecting the Right Abrasive

Choosing the right abrasive is essential for achieving desired results and optimizing efficiency. Factors to consider when selecting an abrasive include the material being worked on, the desired finish, the required rate of material removal, and the specific application requirements.

Conclusion

Abrasives are indispensable materials in various industries, providing the means to grind, cut, polish, and shape surfaces. They come in natural and synthetic forms, each with its unique properties and applications. Understanding the types of abrasives available, their properties, and their applications is crucial for selecting the appropriate abrasive for specific tasks.