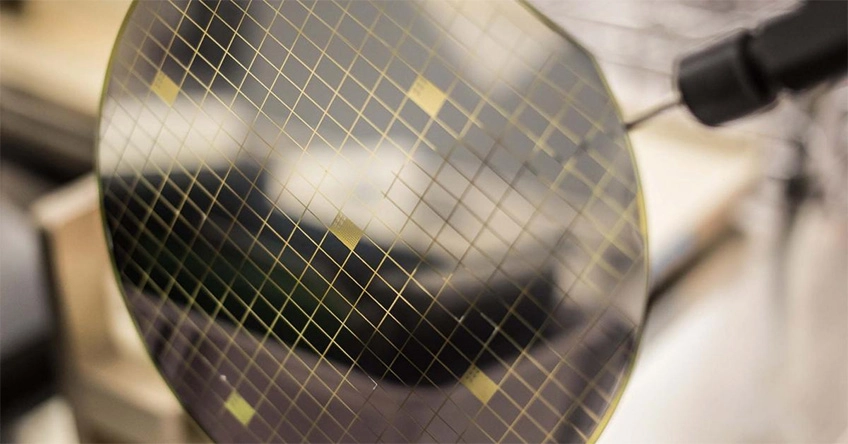

What Are SiC Wafers?

SiC wafers are thin slices of silicon carbide, a compound consisting of silicon and carbon. Unlike traditional silicon wafers, SiC wafers boast unique characteristics, making them highly desirable in the production of power electronics, RF devices, and other high-performance applications. Silicon carbide is renowned for its hardness, high thermal conductivity, and resistance to chemical and thermal degradation.

Key Advantages of SiC Wafers

1. High Thermal Conductivity

One of the primary advantages of SiC wafers is their high thermal conductivity. This property allows devices made from SiC to operate at higher temperatures without compromising performance, making them ideal for applications that involve significant heat generation, such as power converters and inverters.

2. Superior Efficiency

SiC wafers enable the production of semiconductors that are more efficient than those made from traditional silicon. This is because SiC has a wider bandgap, allowing devices to operate at higher voltages and frequencies with less energy loss. This leads to improved energy efficiency, which is particularly important in sectors like electric vehicles (EVs) and renewable energy.

3. Enhanced Durability

SiC is an exceptionally durable material, resistant to wear and tear, chemical reactions, and extreme temperatures. Devices built with SiC wafers tend to have a longer lifespan and require less maintenance, making them more cost-effective over time.

4. Reduced Size and Weight

Because SiC devices can operate more efficiently and handle higher power densities, they can be made smaller and lighter than their silicon counterparts. This reduction in size and weight is beneficial in applications like aerospace and automotive, where space and weight savings are crucial.

Applications of SiC Wafers

SiC wafers are used in a variety of high-performance applications, including:

- **Power Electronics:** SiC is widely used in power converters, inverters, and motor drives, particularly in industries such as electric vehicles, renewable energy, and industrial automation.

- **RF Devices:** The superior properties of SiC make it ideal for radio frequency (RF) applications, including RF amplifiers and wireless communication systems.

- **High-Temperature Applications:** Due to their ability to withstand high temperatures, SiC wafers are used in devices that operate in extreme environments, such as aerospace and military applications.

Conclusion

SiC wafers are paving the way for the next generation of semiconductor technology. Their superior thermal conductivity, efficiency, and durability make them an essential material for high-performance applications. As industries continue to demand more powerful and efficient electronic devices, the role of SiC wafers will only grow in importance.