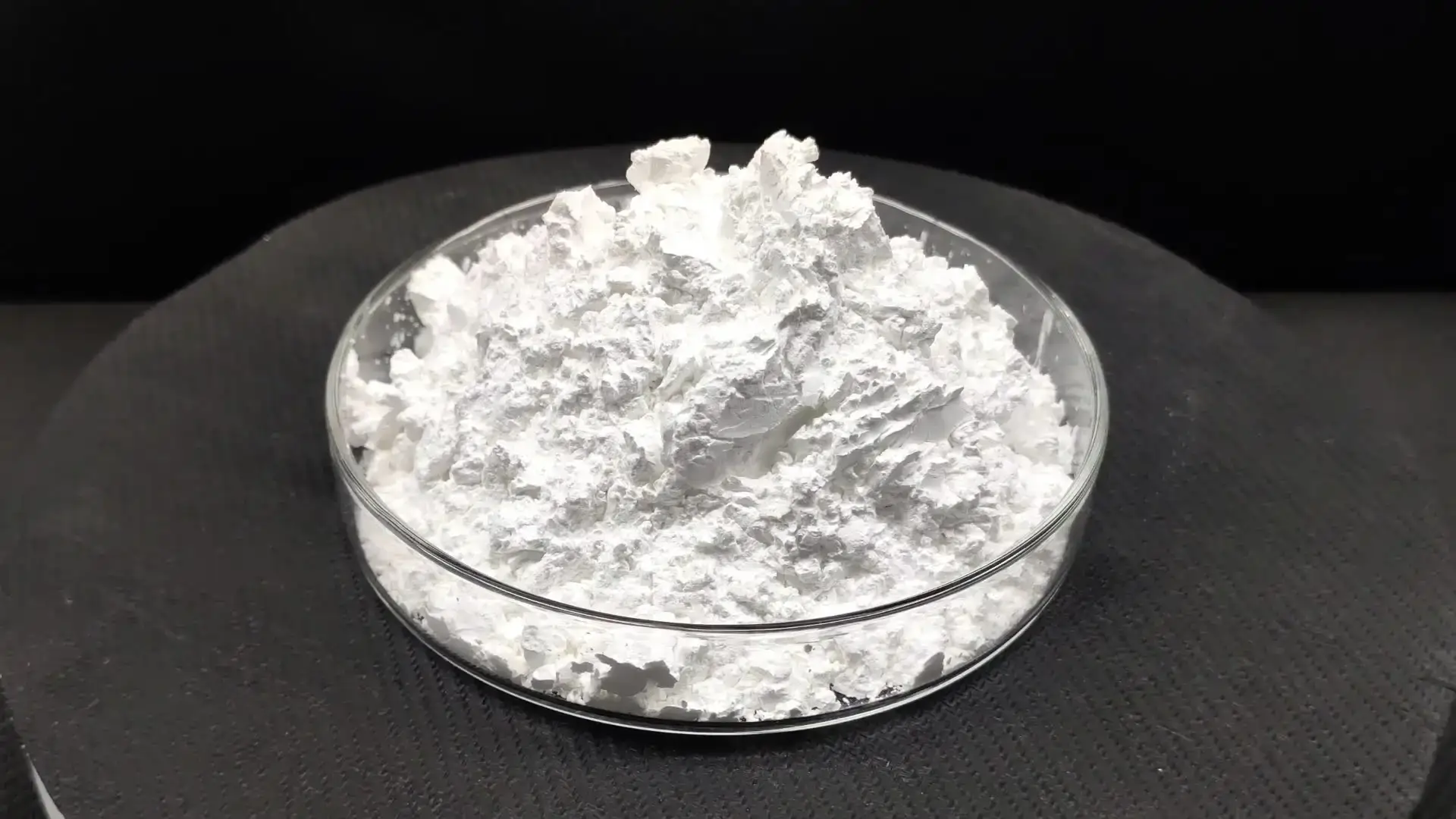

Fused white corundum is a high-performance ceramic material with excellent physical and chemical properties and is widely used in industrial fields. It also has some disadvantages. This article will discuss the advantages and disadvantages of fused white corundum and look forward to its future application prospects.

Advantages:

- High hardness: The hardness of fused white corundum is second only to diamond, reaching level 9.0. This makes it useful in a wide range of applications in areas such as abrasives, grinding and cutting tools.

- Strong wear resistance: Fused white corundum has excellent wear resistance and can maintain stable performance in high-speed, high-temperature and high-pressure environments. Therefore, it is widely used in fields such as abrasives, grinding and cutting tools.

- High temperature resistance: Fused white corundum has good high temperature resistance and can maintain stable physical and chemical properties in high temperature environments. This makes it widely used in high-temperature furnaces, refractories and thermal barrier coatings.

- Good chemical stability: Fused white corundum has good chemical stability and can resist erosion by corrosive media such as acids and alkalis. This makes it widely used in fields such as chemical industry, metallurgy and environmental protection.

shortcoming:

- Expensive cost: The preparation process of fused white corundum is complicated and the production cost is high. This limits its application in some areas.

- High brittleness: Fused white corundum has high hardness, but it also leads to high brittleness. It is prone to fracture when impacted by external force, which limits its application in certain fields.

- Difficulty in processing: Due to the hardness and brittleness of fused white corundum, it is difficult to process. Special processes and equipment are required for processing, which increases production costs and process complexity.

Application prospects:

- Although fused white corundum has some shortcomings, its advantages make it have broad application prospects in many fields.

- Abrasives and Grinding Tools: The high hardness and wear resistance of fused white corundum make it an ideal abrasive and grinding tool material. With the development of industry, the demand for high-precision grinding continues to increase. Fused white corundum has broad application prospects in this field.

- High-temperature materials: The high-temperature resistance of fused white corundum makes it an ideal choice for high-temperature furnaces, refractories, and thermal barrier coatings. With the continuous development of high-temperature processes, the demand for high-temperature materials will continue to increase, and fused white corundum is expected to play a greater role in this field.

- Chemical industry and environmental protection field: The chemical stability of fused white corundum makes it have broad application prospects in the chemical industry and environmental protection field. As environmental awareness increases and chemical safety requirements increase, the demand for chemically stable materials will continue to increase. As a high-performance ceramic material, fused white corundum has many advantages, such as high hardness, wear resistance, high temperature resistance and chemical stability. Despite some shortcomings, such as high cost, brittleness, and difficulty in processing, its application prospects are still broad. With the development of industry and advancement of technology, fused white corundum is expected to play a greater role in abrasives, grinding tools, high-temperature materials, chemical industry and environmental protection fields.