Alumina, also known as aluminum oxide (Al2O3), is a widely used abrasive material due to its hardness, durability, and versatility. It is available in different forms and colors, with white alumina and brown alumina being two common variations. Understanding the differences between these two types of alumina is crucial for selecting the appropriate abrasive material for specific applications. In this article, we will explore the disparities between white alumina and brown alumina, shedding light on their unique properties, applications, and performance characteristics.

White Alumina

Composition and Appearance

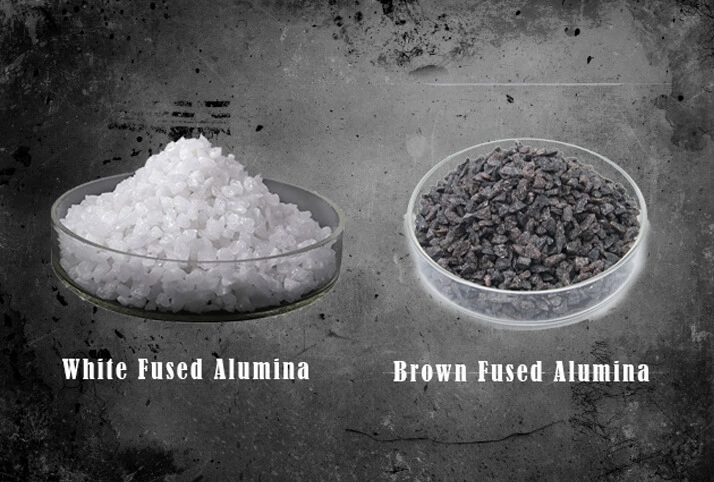

White alumina is a high-purity form of aluminum oxide that is manufactured from high-quality bauxite ore. It is characterized by its pure white color and is often referred to as white corundum. The high purity level ensures minimal impurities, resulting in excellent chemical stability and consistent performance.

Crystal Structure

White alumina possesses a hexagonal crystal structure, similar to natural corundum. This crystal structure contributes to its exceptional hardness and strength, making it highly suitable for abrasive applications.

Key Properties

- Hardness: White alumina exhibits exceptional hardness, ranking just below diamond on the Mohs scale. This hardness ensures its effectiveness in cutting, grinding, and polishing applications.

- High Purity: White alumina is known for its high purity, typically exceeding 99%. This purity contributes to its excellent chemical stability and resistance to heat and corrosion.

- Uniform Particle Size: White alumina is manufactured with a precise particle size distribution, allowing for consistent and controlled abrasive action.

- Low Heat Generation: Due to its high purity and controlled particle size, white alumina generates less heat during abrasive operations, reducing the risk of thermal damage to workpieces.

Applications

- Precision grinding and lapping of optical lenses and components.

- Polishing and finishing of stainless steel, ceramics, and other delicate materials.

- Surface preparation for electronic components, semiconductors, and advanced ceramics.

- Production of high-performance grinding wheels, cutting tools, and abrasive papers.

Brown Alumina

Composition and Appearance

Brown alumina, also known as brown corundum, is derived from bauxite ore through a controlled fusion process. It is characterized by its rich brown color and is widely used as an abrasive material due to its excellent cutting performance.

Crystal Structure

Brown alumina possesses a trigonal crystal structure, similar to natural corundum. This crystal structure contributes to its robustness and durability, allowing for efficient material removal during abrasive operations.

Key Properties

- Hardness: Brown alumina is known for its exceptional hardness, ranking just below white alumina on the Mohs scale. Its hardness ensures effective cutting and grinding performance.

- Toughness: Brown alumina exhibits high toughness and durability, making it suitable for heavy-duty applications and material removal.

- Good Heat Dissipation: The unique crystal structure of brown alumina allows for efficient dissipation of heat generated during abrasive operations, reducing the risk of thermal damage to workpieces.

- Sharp Edges: Brown alumina grains have well-defined edges, providing aggressive cutting action and efficient stock removal.

Raw Material and Production Technology

White alumina is produced from aluminum oxide powder that results from the Bayer process, a method of refining bauxite to obtain alumina. Brown alumina, on the other hand, is derived from calcined natural bauxite ore. Both types of alumina are created using electro fusing technology in electric arc furnaces, which can be either fixed or tilting.

Applications

- Heavy-duty grinding and cutting operations in foundries and steel mills.

- Surface preparation for metal fabrication, such as cleaning, deburring, and descaling.

- Sandblasting and shot peening applications.

- Production of grinding wheels, abrasive belts, and coated abrasives for general-purpose use.

Conclusion

White alumina and brown alumina are two distinct variations of aluminum oxide with unique properties and applications. White alumina, with its high purity and controlled particle size, excels in precision grinding, polishing, and surface preparation applications. Brown alumina, known for its toughness and durability, is ideal for heavy-duty cutting and grinding operations. Understanding the differences between these two types of alumina allows for the selection of the most suitable abrasive material to achieve optimal results in various industrial processes.